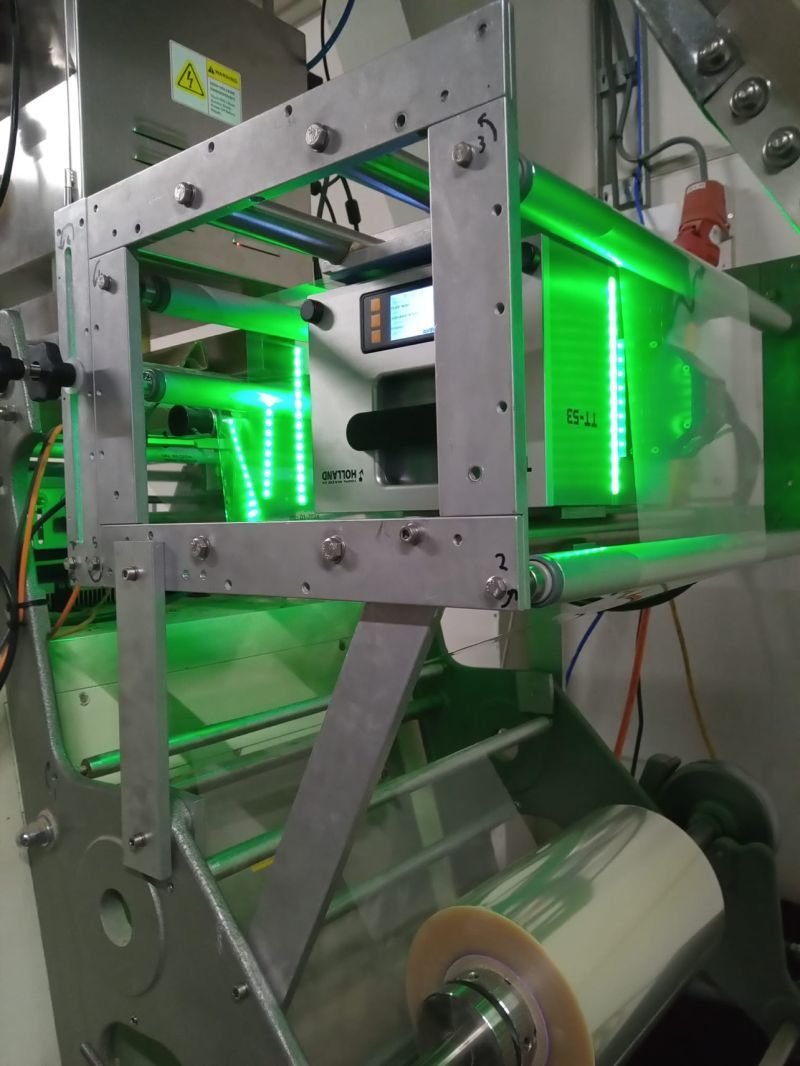

Kortho TT-Series

Always Reliable

Printer ribbon can sometimes break, wrinkle, or become stuck on the take-up spool when the tension is too loose, too tight, or inconsistent. The longer the ribbon, the more likely these problems will occur. But with SMARTFORCE technology, these ribbon problems are solved. The system uses constant electronic regulation to maintain equal and optimal tension, even when not printing, and you won't have to worry about downtime due to ribbon errors or roll changes.

Unconditional Print Quality

The TT-Series printers also use SMARTFORCE technology to electronically position the printhead onto the substrate and regulate the pressure in real time, ensuring perfect contact between the printhead and the product under any condition. Even if the print surface is uneven, bumpy, or sloped, the printhead will adjust to follow the surface trajectory at a constant pressure, compensating for any imperfections. This makes the TT-Series highly adaptable to changing and non-optimal conditions, resulting in consistently high print quality.

Key Features

Compatibility

Kortho not only provides its own Control Center LMS software, but also enables compatibility with various third-party label and control software. This allows you to choose the software and control method that best suits your needs. You can easily implement smart, customized, and error-free coding. The printer adjusts itself to meet your coding needs, making it easy to meet any custom requirements.

Control Centre

Control of the Kortho TT-Series is based on an open platform and Windows OS, and it has extended options for communication with other third-party software. It includes a Windows generic network driver and over 350 different commands, and it can help save costs by allowing multiple printers to be controlled from a single terminal. Additionally, users can monitor production data and statistics from the printer, and use variable Machine IDs to get updates on production status.

Ribbon Technology

SMARTFORCE technology controls the tension of the ribbon to prevent any issues, enabling the use of the longest ribbon available, and real-time ultrasonic ribbon indexing ensures precise and reliable ribbon transport without the need for moving parts (encoders). The space between ribbon waste during printing is maintained at an average of no more than 0.5mm, optimising ribbon consumption.

Printhead Capability

The Kortho TT-Series automatic printhead positioning places the printhead in the best position relative to the substrate, which makes it adaptable to varying conditions. Changing the orientation of the printhead is simple, allowing the printer to handle Intermittent, Continuous Left, and Continuous Right printing, making it suitable for all types of applications. The printhead is kept at an operational temperature, helping to significantly prolong its lifespan and enabling it to produce high-quality prints even in cold or humid environments.

Tech Specs & Dimensions

T-53

| Print Unit Dimensions | 195 x 294 x 249 mm |

| Print Unit Weight | 10.3 kg |

| Max Print Area I-mode | 53 x 95 mm |

| Max Print Area C-mode | 53 x 200 mm |

| Max Print Speed | 600 mm/sec |

| Resolution | 300 DPI |

| Print Modes | Intermittent and Continuous L & R in any orientation |

| Connectors | Free configurable I/O port; Ethernet; USB; Power; Encoder |